Product News

Austmine and AROSE are exploring opportunities with NASA, as the agency queries the Australian Mining, Equipment, Technology, and Services (METS) sector for groundbreaking solutions to aid off world exploration. This is an exciting opportunity for the Australian METS community to present their capabilities to NASA and other US Agencies.

Shortlisted companies will have the chance to present their solutions at the NASA-USGS Workshop in San Jose, California in May, offering unprecedented exposure and recognition on an international platform.

Australia boasts a small but rapidly growing space industry alongside a highly innovative METS sector. Over the past year, there has been a notable increase in interest from both the Australian Space Agency and NASA in the mining and METS sector. This heightened interest reflects the recognition of the overlap between space exploration and mining ... more

Idemitsu Australia invests in Graphinex

Idemitsu Australia, a prominent player in the energy sector, has announced a significant strategic investment in Graphinex Pty Ltd, a private graphite battery anode company.

This investment, made through Idemitsu's wholly owned subsidiary, Idemitsu Graphite Pty Ltd, is said to highlight the company's commitment to advancing sustainable technologies and supporting the growth of the battery industry.

Graphinex holds a portfolio of exploration tenements near Croydon, in Queensland’s northwest minerals province, including the flagship Esmeralda Graphite Project.

Graphinex Managing Director Art Malone said: "This marks a pivotal moment for Graphinex, as Idemitsu’s strategic investment and support propels us forward in our journey to supply Battery Active Anode Material and Spherical Graphite to global battery manufacturers, empowering the transition towards cleaner energy solutio... more

Sedgman continues to strengthen position in critical minerals sector

Sedgman, a member of the CIMIC Group, has announced the acquisition of MinSol Engineering Pty Ltd — a move that marks its third acquisition in the critical minerals processing sector.

This strategic acquisition completes Sedgman's vision of becoming a full-service, global provider in the extraction and refining of minerals essential to the rapidly growing clean energy technologies.

MinSol Engineering, based in Western Australia, specialises in engineering design and project management for mineral processing facilities and associated infrastructure.

The company's core business focuses on engineering hard rock lithium concentration and refining processes — including metallurgical test work, flowsheet development, and detailed design.

The acquisition of MinSol Engineering allows Sedgman to expand its capabilities in the critical minerals processing sector, particularly in ha... more

Liebherr reported major growth and investments in 2023

Liebherr's revenue experienced a significant increase compared to the previous year, with growth in 11 of its 13 product segments. The company surpassed its 2022 revenue record by €1,453 million (approximately AU$2.3 million), reaching a total revenue of €9,557 million (approximately $AU15.7 million).

This growth was driven by the earthmoving, material handling technology, deep foundation machines, mobile and crawler cranes, tower cranes, concrete technology, and mining product segments, which saw an 11.6 per cent increase over the previous year.

Liebherr experienced positive growth in nearly all sales regions, with particularly strong revenue increases in the European Union, Germany, France, Spain, North America (particularly the USA and Mexico), Asia, Oceania, and the Africa, Near and Middle East region. Central and South America, however, saw revenue remain stable.

The co... more

NSR Hire opens new branch in Karratha

In a strategic move aimed at bolstering its presence in the Pilbara region, NSR Hire has just unveiled its latest venture – a brand-new branch in Karratha.

This development marks a significant milestone in the company's expansion strategy, further solidifying its commitment to serving clientele in the Western Australian region.

The inauguration of the Karratha branch promises a plethora of benefits for both existing and prospective customers.

By establishing a local presence, NSR aims to streamline operations and significantly reduce delivery times, offering unparalleled convenience to project sites in the vicinity.

This move underscores the company's dedication to enhancing customer experience and fostering stronger relationships within the community.

NSR Hire is the civil, mining and construction division of Northside Rentals and has two other branches located in Newm... more

Epiroc releases new long feed version of SmartROC C50

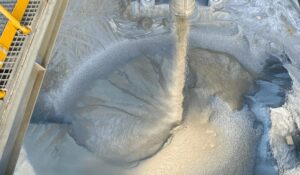

The class-leading SmartROC C50 will now be available with a choice of two feeds, the standard feed or a long feed.

This rig combines high penetration rates with superior hole quality – even in the most challenging conditions.

The long feed enables this COPROD rig to deliver even more metres per shift by increasing drilling time and reducing the time changing rods.

Additionally, less rod changing reduces wear on consumables and helps lower fuel costs. This makes this machine even more cost effective.

The SmartROC C50 is one of fastest, safest, and most efficient drill rigs available on the market.

The well-known surface drill rig is a favoured choice for contractors and mining customers who require both raw power and precision.

This is due to the COPROD technology, which offers the unique combination of precision and speed.

Together with the new long feed this rig w... more

MEC Mining expands into Environmental Services Portfolio with strategic acquisition of METServe

The Australian-based global technical services firm, MEC Mining continues its substantial growth in the resources sector with the recent acquisition of environmental services company METServe.

The combined service offering will encompass all aspects of environmental services previously provided by METServe. This includes approvals, impact assessment, environmental management, closure and rehabilitation, ecology, social, GIS analysis, cartography, and more.

MEC Mining CEO, Christofer Catania highlighted that the acquisition complements MEC’s portfolio. “METServe has a 20-year history of working within industry on successful project approvals across the federal, state, and territory levels in Australia.”

“It’s exciting to bring METServe into the MEC group, our combined services offerings and mutual focus on supporting our clients as journey partners makes this a fantastic st... more